The manufacturing process of vacuum-brazed diamond coring drill bits involves a complex series of steps to ensure the production of a high-quality, durable drill tool. These drill bits are critical for a variety of industrial applications, including construction, mining, and infrastructure development. The process begins with meticulous material inspection and preparation to ensure concentricity and overall dimensional accuracy of the steel matrix. This article provides a detailed overview of the manufacturing process from material preparation to final packaging, highlighting the precision and expertise required at each stage.

Material Inspection And Preparation

The first step in the vacuum-brazed diamond core drill bit manufacturing process is to carefully inspect the material and ensure the concentricity of the steel matrix. This involves rigorous quality checks to verify the integrity and dimensions of the substrate, as well as the cleanliness and dryness of the material. Any deviations from specified requirements are carefully addressed to maintain the highest standards of accuracy. Once the material passes inspection, it goes through a thorough cleaning process to remove any rust and oil stains. This is achieved by using specialized machines to evenly blast the material, effectively preparing it for subsequent stages of the manufacturing process.

Application Of Special Glue And Placement Of Diamond Particles

After material preparation, a key part of the manufacturing process is the application of special glue to the working layers of the product. The purpose of this step is to promote adhesion of the diamond particles to the substrate, ensuring a strong and long-lasting bond. The application of special glue requires precision and expertise to achieve even coverage throughout the working layer. Skilled workers then manually sprinkle the diamond particles onto the working layer, ensuring an even distribution for optimal drilling performance. This meticulous process is critical to achieving an exceptional bond between the diamond particles and matrix, laying the foundation for the drill's exceptional durability and cutting efficiency.

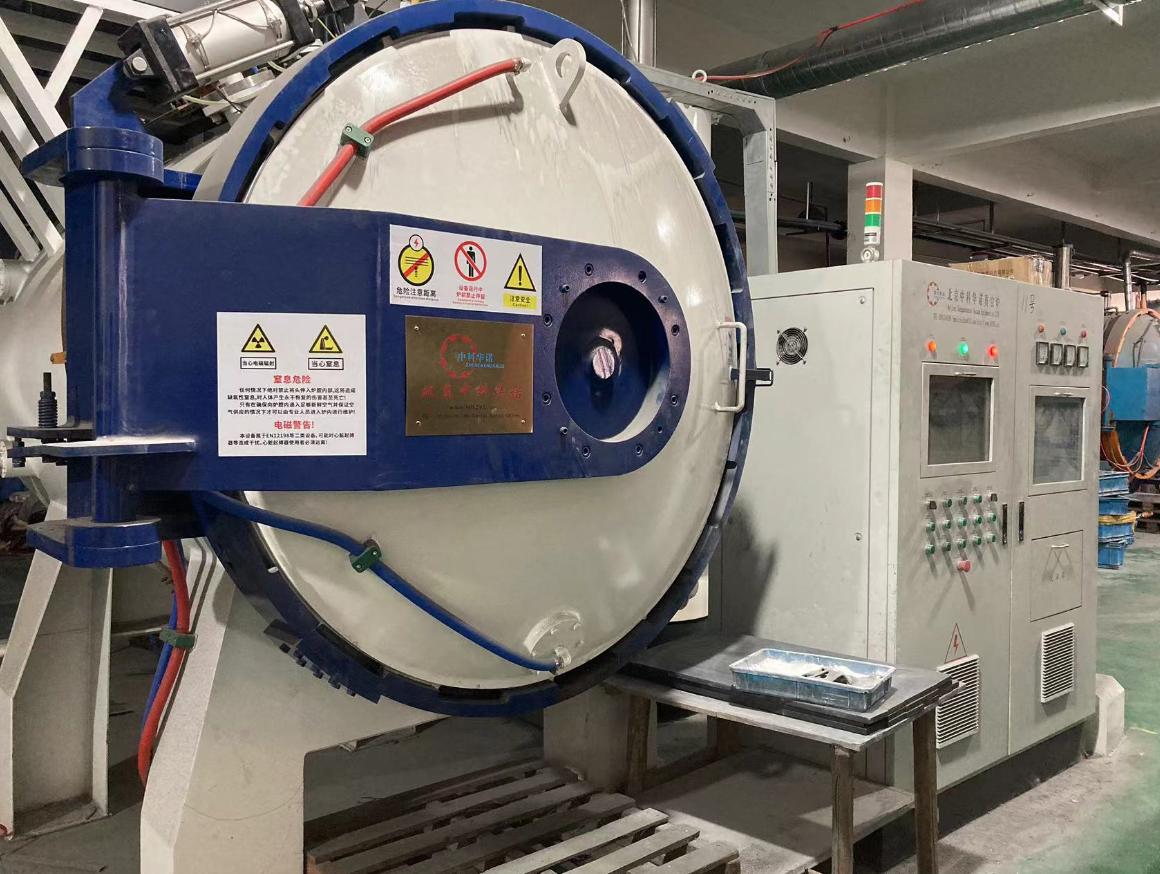

Brazing Processes And Thread Refinement

Once the diamond particles are evenly distributed on the working layer, the drill bit is placed into the brazing furnace for the brazing process. This critical stage involves subjecting the drill bit to high temperatures to firmly embed the diamond particles into the matrix. The brazing process is carefully controlled to ensure optimal bonding of the diamond particles and matrix, resulting in a strong and reliable bond. After the brazing process, the threads of the drill bit need to be re-threaded to improve the concentricity and accuracy of the threads. This meticulous refinement ensures the drill bit meets the exact specifications required for precise, efficient drilling operations.

Spray Painting, Laser Marking, Anti-rust Treatment

After the brazing and thread refining stages, the drill bit undergoes additional finishing processes to enhance its functionality and durability. Skilled factory workers carefully hand-paint the drill bits, applying a protective coating to protect the surface and enhance the overall beauty. After the paint has been applied, the bit is allowed to dry thoroughly to ensure a long-lasting and even finish. The drill is then laser-marked with important information, including product specifications and brand details. This precise marking process adds a layer of authenticity and traceability to the drill bits, allowing for easy identification and quality assurance. After laser marking, anti-rust oil is applied to the marked area to provide an additional layer of protection against corrosion and ensure the service life of the drill bit in various working environments.

Packaging And Quality Inspection

The final stage of the manufacturing process includes careful packaging of the drill bits according to customer requirements. This includes meticulous attention to detail in packaging design, labeling, and protective measures to ensure the drill reaches the customer in the best possible condition. Strict quality checks are conducted throughout the entire production process to detect any deviations or defects. Any nonconforming product will undergo rework or corrective action to maintain the highest quality and accuracy standards. This comprehensive quality control approach ensures that every vacuum-brazed diamond core drill bit leaving the factory meets the stringent requirements of industrial applications, delivering reliable performance and durability.

In Conclusion

The manufacturing process of vacuum brazed diamond coring drill bits is a testament to precision engineering and meticulous craftsmanship. From initial material inspection and preparation to final packaging and quality inspection, every stage of the process is characterized by a commitment to excellence and quality. The combination of advanced technology, skilled craftsmanship and strict quality control measures ensures that the drill bits produced meet the demanding requirements of industrial drilling operations. By adhering to the highest manufacturing standards, vacuum brazed diamond coring drill bits remain an indispensable tool in a variety of applications, contributing to efficiency and productivity in various industries.